PSU helps the Navy learn 'the art of the possible'

Its scientists have developed "anti-torpedos" - seafaring interceptors akin to Patriot missiles. They're designing new navigation systems to allow sailors and soldiers to know where they are when GPS isn't available.

Its scientists have developed "anti-torpedos" - seafaring interceptors akin to Patriot missiles.

They're designing new navigation systems to allow sailors and soldiers to know where they are when GPS isn't available.

They're working on a new fuel made from aluminum powder and seawater that would let unmanned vehicles stay in the depths longer as they hunt down enemy mines.

Without fanfare, this work - much of it top secret - goes on in a nondescript building on Pennsylvania State University's main campus, the Applied Research Laboratory, which conducts more than $200 million in research each year, the bulk of that for the Navy.

Its leaders, touting the lab's 70th anniversary of developing new technologies, recently offered a glimpse inside the main building and its other sites, including a saucer-shaped facility in Warminster, where engineers test precision navigation for submarines.

"We help the government figure out the art of the possible," Allan Sonsteby, deputy executive director, said at lab headquarters, a basic brick building next to the university power plant in State College.

The scientists recently designed the propulsor system that will go on a new attack submarine. They were challenged to make the blades cut through the water as soundlessly as possible.

"The crown jewel for submarines is how quiet can they be," said Paul E. Sullivan, a retired Navy vice admiral and director of the laboratory. "Noise is death."

To enter the laboratory requires passing through tight security. iPhones must be left at the door.

At its Garfield Thomas Water Tunnel, one of the world's largest facilities of its kind, workers test submarine propellers and other devices. One recent afternoon, a visitor was not allowed to look inside the tunnel, where 106,000 gallons of water can flow through at 60 feet per second.

Classified testing was underway.

The nation's 13 university-affiliated research centers grew out of World War II, when U.S. leaders wanted to forge closer relationships between scientists and the military.

At Penn State, the lab answers the call of the Navy.

Close to a decade ago, the request was: Can you kill an incoming torpedo? The Navy wanted better protection for its aircraft carriers, 6,000-person cities at sea for months at a time. Out came the lab's anti-torpedo. The first one went on the USS George H.W. Bush carrier in 2012.

Later, they were added to the USS Theodore Roosevelt, which recently was featured in Penn State's alumni magazine because more than a dozen alumni serve on the crew.

The applied research lab employs 1,200, including a couple hundred students. Sullivan reports to Penn State's vice president of research. Many lab employees also teach.

And professors in other disciplines sometimes come out of the classroom to do research for the Navy. A liberal arts professor, expert in how other cultures learn, currently is helping the Navy understand how young sailors acquire knowledge.

"They are out there launching $75 million aircraft at age 19, 20. They can't make mistakes," said Sullivan, who spent 34 years in the service and joined Penn State in 2014.

The lab helps the defense department financially, too, Sonsteby said. Its automated process for sanding rivets - fasteners used aboard Joint Strike Fighter planes - is expected to save the military hundreds of millions, he said. Each plane has 44,000 rivets; they used to be hand-smoothed.

"Instead of taking three minutes per rivet," Sonsteby said, "it's under a minute now."

Some work is not classified. The additive manufacturing lab stepped up when the Navy announced intentions to put 3-D printers on aircraft carriers to manufacture boat parts by 2017.

"We quickly got a call, saying, 'Help,' " said Tim Simpson, lab codirector and a mechanical and industrial engineering professor.

The 3-D parts can be lighter, better performing, more intricate, and less expensive, Simpson said.

Some work is done for nonmilitary entities.

The lab, he said, helped with 3-D printer-made titanium hip implants that allow patients to recover more quickly because bone can grow into them.

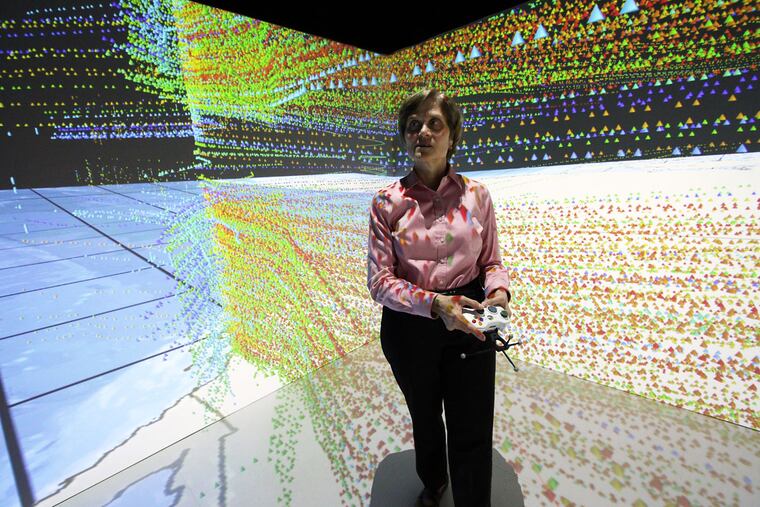

Penn State's Pegula Ice Arena was designed in part at the applied science building, in a 10-by-10-foot immersive 3-D "cave" with screened walls. Benefactors Terry Pegula and his wife walked through a virtual version of the arena and pointed out changes they wanted to see. They asked that second-floor walls overlooking a community ice rink be changed to glass so that people could watch skaters, said Eileen Rotthoff, lab research assistant.

Penn State saved nearly a half million because architects could make building adjustments at the virtual stage, she added.

The same technology helps the Joint Interagency Task Force South in Key West, Fla., ferret out illicit drug traffic. The military agency oversees 42 million square miles of ocean. Four Penn State research lab scientists work in the building.

Scientists upload large data sets - such as locations of boats, submarines, and planes - then view them in 3-D, looking for anomalies.

"If you looked at a million points on a desktop, all you'd see is a big blob," Rotthoff said. "Here, you can move through them."

To demonstrate, she uploaded data on flights in and out of the Los Angeles airport. Colorful points and lines on the screen revealed gaps where planes don't fly.

"You know what the best system in the world is for detecting anomalies?" Sonsteby said. "Your mind."

The heart of the 30-acre Warminster site is a nearly windowless building, with a circular roof and special lighting, all conditions designed to eliminate any outside noise or vibrations. Its power is generated in a separate nearby building.

"The reason for this is so we can do the most precise navigation work," director Herb Seligman said.

At the site, which Penn State acquired in 1996, some current research centers on "assured navigation," how to find a location without GPS by starting out with a known position and using various sensors.

Students from Penn State and other universities intern at the lab - and sometimes get jobs there.

"The goal is to help soldiers and seamen to know where they are and to do their jobs effectively," said Dave Redington, 33, a Drexel grad and electrical engineer, "and so that's, I believe, a noble venture."

215-854-4693@ssnyderinq