Meet Hubo the Robot

In movies and TV shows, robots often resemble their human creators - with arms, legs, and a head sitting atop an upright body.

In movies and TV shows, robots often resemble their human creators - with arms, legs, and a head sitting atop an upright body.

In the real world, they almost never do.

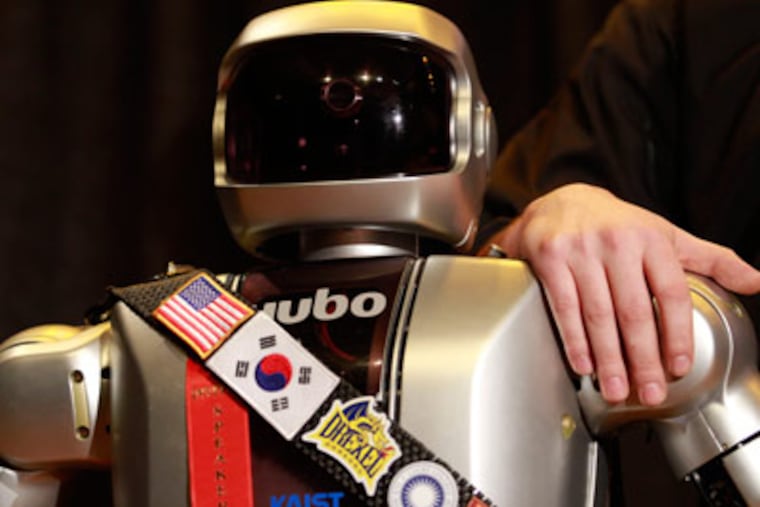

So it was with a certain amount of fanfare that Drexel University engineers assembled seven humanoid robots on a stage last week. Measuring 4 feet, 3 inches tall, they are among the most advanced such machines in the world, with precision motorized joints that mimic most features of the human body.

Built by a partner university in South Korea and customized by Drexel engineers, the robots gyrated and swung their arms in time with a pulsating beat. One of the 'bots demonstrated a good sense of balance, shifting its weight when a child was invited to try to push it over.

Drexel is leading a group of seven other schools, including the University of Pennsylvania, that will study and customize the machines, funded by a $6 million, five-year grant from the National Science Foundation.

By now, a question that the engineers are accustomed to hearing is "Why?"

As in, why mimic the human form? What's so great about an upright, two-legged being that, notwithstanding the balance demonstration at Drexel, can fall down?

Potential applications could include tasks that are dangerous, such as hazardous-site cleanup and rescue, and jobs that are merely tedious, such as washing dishes and putting them back in the cupboard.

To tackle a range of jobs in a world designed by and for humans, using a humanoid robot makes sense, say Drexel faculty members Youngmoo Kim and Paul Oh.

"Having a robot that can deal with the world as it is, with stairs and curbs and odd-shaped doorknobs - a humanoid lends itself to overcoming those problems," Kim said.

But to hear Oh talk about the subject, he seems drawn by the simple fact that a humanoid robot is cool. The specific applications can come later.

"If you asked the Wright brothers, 'Hey, what's the practical application of the airplane?', or if you asked what was the application of going to the moon, a lot of the people dreaming these things weren't thinking that way," Oh said.

With their somewhat limited capabilities (for now) and high cost, humanoid robots probably will not be everyday items for many years, perhaps decades. There are just a handful of models at the same level as the ones Drexel is using, and you cannot just buy them at a store.

Kim estimated that the models at Drexel cost well into six figures for the parts alone, not counting research, development, and labor.

They are the work of KAIST - Korea Advanced Institute of Science and Technology, located in Daejeon, about two hours south of Seoul. Called Hubo, short for humanoid robots, the machines are built in a lab directed by Jun-Ho Oh.

Korea and Japan are world leaders in humanoid robots, especially the hardware side, whereas the United States is considered tops in artificial intelligence.

So one of the tasks for Drexel, Penn, and the other U.S. schools is to upgrade Hubo's brain and nervous system. That means adding high-resolution cameras for binocular vision, an array of microphones, and, from partners at the University of Southern California, synthetic gloves that give the machines a sense of touch.

All of which will require the U.S. engineers to write complex software, so the machines can make sense of and react to their surroundings.

Though the robot work with Korea is a research project, when Oh began it several years ago he also saw it as a vehicle for international collaboration.

U.S. engineering students are far less likely than their international counterparts to enter the workforce with experience working abroad, a drawback in an era of increased globalization, Oh said.

The fact that he and the Korean lab director share the name Oh is no coincidence. The two are first cousins.

Jun-Ho Oh started developing the first Hubo more than a decade ago. In 2007, Paul Oh got a grant that would enable his students to obtain experience at the lab in Korea.

Alex Alspach and Sean Mason, both fifth-year seniors in Drexel's mechanical engineering program, spent six months at the lab in Daejeon, from September 2010 to March of last year. Both said they liked it so much they are now considering jobs abroad as well as in the United States.

Before that, there is work to be done on the machines.

Silver-hued and broad-shouldered, they are lined up in Kim's lab, ready for tinkering.

One day last week, Ph.D. students Alyssa Batula and David Grunberg carefully removed the plates that covered one robot's head and chest, revealing an intricate array of wires, motors, and circuit boards.

The machine's brain - actually brains - can be found in its chest. Two computers are installed side-by-side, atop a lithium polymer battery.

Students have become adept at taking the robots apart and putting them together, and at tweaking their software.

They are less adept at the Korean language.

Grunberg, who also visited Korea, said there was one phrase he wished he had learned in advance.

"Beware of dogs," Grunberg said. "That would have been helpful."

But he and his colleagues say that in the language of engineering and robotics, they understand their Korean counterparts just fine.

Watch Drexel's new robots get down and boogie. Go to www.philly.com/ robots.EndText