No battery? No problem. At Penn, a mini-electric car draws energy from its surroundings.

The technology also could run a generator during a power outage, with no noise or fumes.

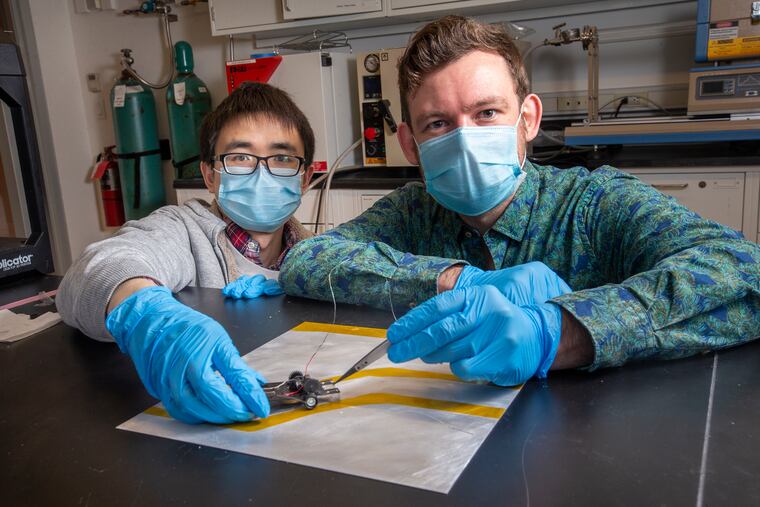

Min Wang placed the miniature electric car on a sheet of aluminum, and immediately — despite having no battery — the vehicle began to move.

Its power supply was the metal beneath it, with an assist from oxygen in the surrounding air.

The demo took place in the University of Pennsylvania lab of James Pikul, an assistant professor of mechanical engineering, who watched as Wang, a doctoral candidate, picked up the car to adjust its gears. Loosely speaking, it works the same way animals oxidize food to get energy, except that the fuel is metal.

“Basically,” Pikul said, “the car eats metal and breathes air.”

It is small — little bigger than a deck of playing cards — but that’s the point. Pikul envisions that the concept could be used in self-powered robots that are even smaller, approaching the size of insects. Such a device could be equipped with sensors to detect leaks as it crawls along a metal pipeline, or fitted with a camera to locate survivors as it clings to the beams of a collapsed building, he said.

These days, it’s no trouble to make computer circuits small enough to mount on such devices. But powering them is a problem, as the smallest robots can carry only enough battery power to last for a few minutes, Pikul said. Hence the idea of scavenging for energy in the environment.

Plenty of other technologies fall into the same broad category of energy “harvesters,” such as solar panels and devices that convert vibrational or thermal energy into electricity. But pound for pound, metal beats most other such approaches. Its chemical structures are unusually rife with latent energy, rivaling the energy density of gasoline, Pikul said. Aluminum is sometimes used as solid fuel for rockets, after all.

And robots at the size Pikul envisions consume tiny amounts of metal, leaving behind a trail of oxidized metal just millionths of a meter deep. The idea might not make sense on a larger scale, say, in a locomotive, as the tracks eventually would need to be replaced. But with small devices, the impact on the metal is imperceptible. The approach works with zinc and iron, too.

“With devices using this technology, any time there’s a metal source nearby, they can operate for free,” he said.

Pikul, Wang, and colleague Yue Gao described the technology in a recent paper in the journal Advanced Intelligent Systems.

Kevin Chen, a Massachusetts Institute of Technology robotics researcher who was not involved, said the work by the Penn engineers could be very promising.

“Professor Pikul is addressing one of the most challenging problems in robotics,” he said. “Being able to take energy from the environment is potentially very high impact in my field.”

» READ MORE: Testing how navigable SEPTA is, with glasses that see what riders see

In the meantime, a Philadelphia-based start-up company called Metal Light already has licensed the technology for a different application: backup power for homes and businesses. Its founders, who include students at Penn and Johns Hopkins University, won a $10,000 prize in 2020 for their business plan, in a competition held by Penn’s engineering and Wharton schools. (Pikul is now an advisor to the company and has a stake in it.)

An early prototype measures 5 inches across, featuring a bright LED light that is fueled by small sheets of metal inserted in one side.

The company is now developing a larger, 2-kilowatt device for use as a generator during power outages, said Wharton student Minhal Dhanjy, one of the founders. Unlike its gasoline counterparts, it would produce no toxic fumes and no noise, meaning it could operate inside, powered by prefab “cassettes” of aluminum.

“We’re estimating it would last three hours on a single cassette,” Dhanjy said.

Future versions could be made to accommodate pieces of scrap metal, making it a great fit for developing countries, he said.

Whether the idea is used in a generator or a robot, two chemical reactions are involved. The metal combines with a corrosive substance such as potassium hydroxide, yielding a flow of electrons: electrical current. The electrons travel from the metal through whatever device is being powered, combining with water and oxygen from the surrounding air to complete an electrical circuit.

The same concept is used in hearing aid batteries, which are activated once a colorful sticker is removed, allowing air to penetrate inside and activate the chemical reaction that yields electricity. But in Pikul’s concept, the car or robot uses its environment as the battery.

In the case of the car, the hydroxide ions are stored in cubes of clear material called hydrogel, similar to what is used to make contact lenses. The cubes are located beneath the “bumper” at the front of the car, feeding hydroxide ions to the reaction as the vehicle rolls along. The electrons then flow from the metal into the car through a pair of trailing wires.

It works great, so long as metal is nearby. That key requirement prompted Pikul and his colleagues to add a new feature to their car earlier this year: enabling the vehicle to “search” for metal in its environment. The car is wired in such a way that if the hydrogel cube on one side encounters a non-metal surface, the wheels steer the vehicle in the other direction, almost as if it is sniffing for food.

“It can sense the chemistry in its environment, and follow the energy trail to get where it needs to go,” the Penn researcher said.

But is there really that much metal in a typical building environment? More than you might think.

Standing in the airy atrium of the Singh Center for Nanotechnology, where his lab is located, Pikul looked around for metal surfaces that might drive his devices. His eyes came to rest on an aluminum support beam that traversed the building’s expansive front window, looking out on Walnut Street in West Philadelphia.

“This would be a great power source,” he said, running his hand up the metal approvingly.

And if such a robot needed to get across a nonmetal surface, that could be arranged. While these mini devices cannot hold a big enough battery for long-term supply, Pikul envisions fitting them with smaller, rechargeable batteries. The robot could pause on metal surface, charge itself up, then scurry ahead to the next metallic source of energy.

The idea might even work outside, powering drones that could hop from stop sign to stop sign, he said. Just a few nibbles of metal at a time.